2024 Hot Sale Epoxy Resin Marble Adhesive Marble Reinforcement

Overview

Epoxy resin is a synthetic polymer with excellent adhesion, chemical resistance and mechanical strength. It is often used as a binder for stone slabs to enhance structural integrity, durability and permeability, ensuring its beauty and practicality.

Product Description

Describe epoxy resin

Epoxy resin has excellent adhesion, chemical resistance, and mechanical strength (all of which are characteristics of synthetic polymers). Epoxy resin is often used as an adhesive to improve the structural integrity and durability of stone. It can effectively fill small cracks and holes on the surface of stone, give the stone a smooth surface effect, increase the permeability and wear resistance of marble, thereby ensuring the beauty and practicality of the product during use.

Product Features

Origin: China

Main raw material: epoxy resin

Application: construction

Name: epoxy adhesive

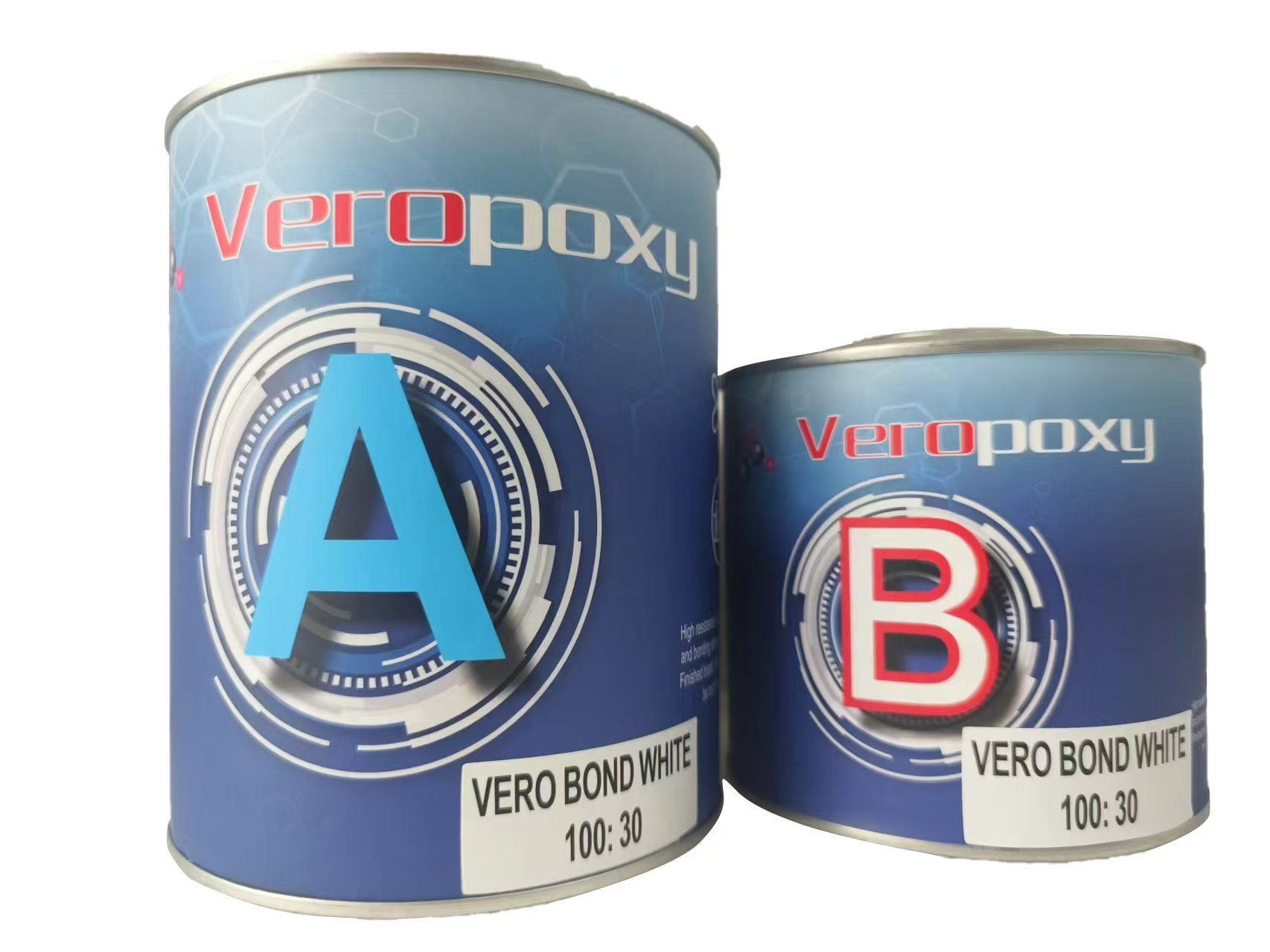

Classification: two-component adhesive

Brand: Veropoxy

Adhesive type: resin epoxy resin

Application: rough surface coating and sealing

Ap4plied Domains

The stone sector mostly uses this epoxy resin for the installation and maintenance of premium materials such marble, granite, and quartz. Vero Bond Epoxy resin is not only fit for stone splicing in house décor but also extensively applied in stone installation in outdoor constructions because of its great strength. This epoxy resin may create great bonding effects for kitchen counters, bathroom walls, or outside stone decorations.

How to apply?

First clean the surface to be glued to Vero Bond Epoxy resin to guarantee that there are no contaminants such dust and grease. Next mix component A and component B in proportion (100:25), stir uniformly, then apply to the surface to be bonded. To get a strong bonding effect, then align and press the two pieces of material, let them stand for many hours, and let the glue totally dry.

Preventive Measures

Keep the workspace well ventilated and be cautious not to direct Vero Bond Epoxy resin straight towards the skin or eyes. Remaining adhesive should be sealed in time following usage to stop air from entering and resulting in cure failure. Simultaneously, closely observe the mixing ratio to guarantee the best bonding effect.

Whether in home decoration or professional engineering, Vero Bond Epoxy resin is a dependable choice. For all sorts of stone and composite materials, its great adhesion, weather durability, chemical corrosion resistance, along with environmental protection and safety, make it the perfect glue. Vero Bond Epoxy resin is surely a reliable option if you search for a high-performance bonding solution.

Company Profile:

Veropoxy was founded in 2012 and has partnered with an Italian epoxy company specializing in the stone industry to formulate epoxy resins for the grid and top finishes of marble and granite slabs.

Epoxy resins are a synthetic material with extensive and excellent performance in industry and construction. The two components are resin and hardener; they cure 100% at room temperature or under heating to form a hard, plastic-like material. Excellent bond strength, chemical resistance, heat resistance and electrical insulation make epoxy resins the material of choice. Veropoxy has been dedicated to developing and formulating specialized epoxy resins for a variety of stone materials.

Marble slabs are particularly prominent in the use of epoxy resins. Not only does it provide a protective layer that increases the wear and impact resistance of marble, it is also water-resistant and UV-resistant, thus making the slab beautiful and durable in both indoor and outdoor environments. While the self-leveling properties of epoxy resins ensure a smooth, ripple-free surface, its excellent transparency and glossiness highlight the natural texture of the marble. Additionally, epoxy is a perfect choice for marble slabs because it cures quickly, is simple to work with, and produces a material that is easy to repair and clean.

How to apply

First clean the surface to be glued to Vero Bond Epoxy resin to guarantee that there are no contaminants such oil and dust. Next mix component A and component B in proportion (100:25), stir uniformly, and then brush the surface to be glued. Then, align and push the two pieces of material together; let them stand for several hours to let the glue totally dry; you will thus have a strong bonding effect.

Strategies

Keep the workspace well ventilated and be cautious not to direct Vero Bond Epoxy resin straight towards the skin or eyes. Remaining adhesive should be sealed in time following usage to stop air from entering and resulting in cure failure. Simultaneously, combine strictly in line with the percentage to guarantee the best bonding effect.