diy epoxy resin stone

Overview

The Vero Bond Epoxy resin, a two-component adhesive, is a strong and weather-resistant option for connecting materials like marble and granite, making it a top choice in the stone sector for durability and quality.

Product Description

Selecting the correct adhesive in the stone sector guarantees building endurance and quality. Designed for connecting a range of materials including marble and granite, two-component super-strong adhesive Vero Bond Epoxy resin is Vero Bond glue has become among the strongest epoxy resins in the stone sector with its great adhesion and good weather resistance.

Product traits

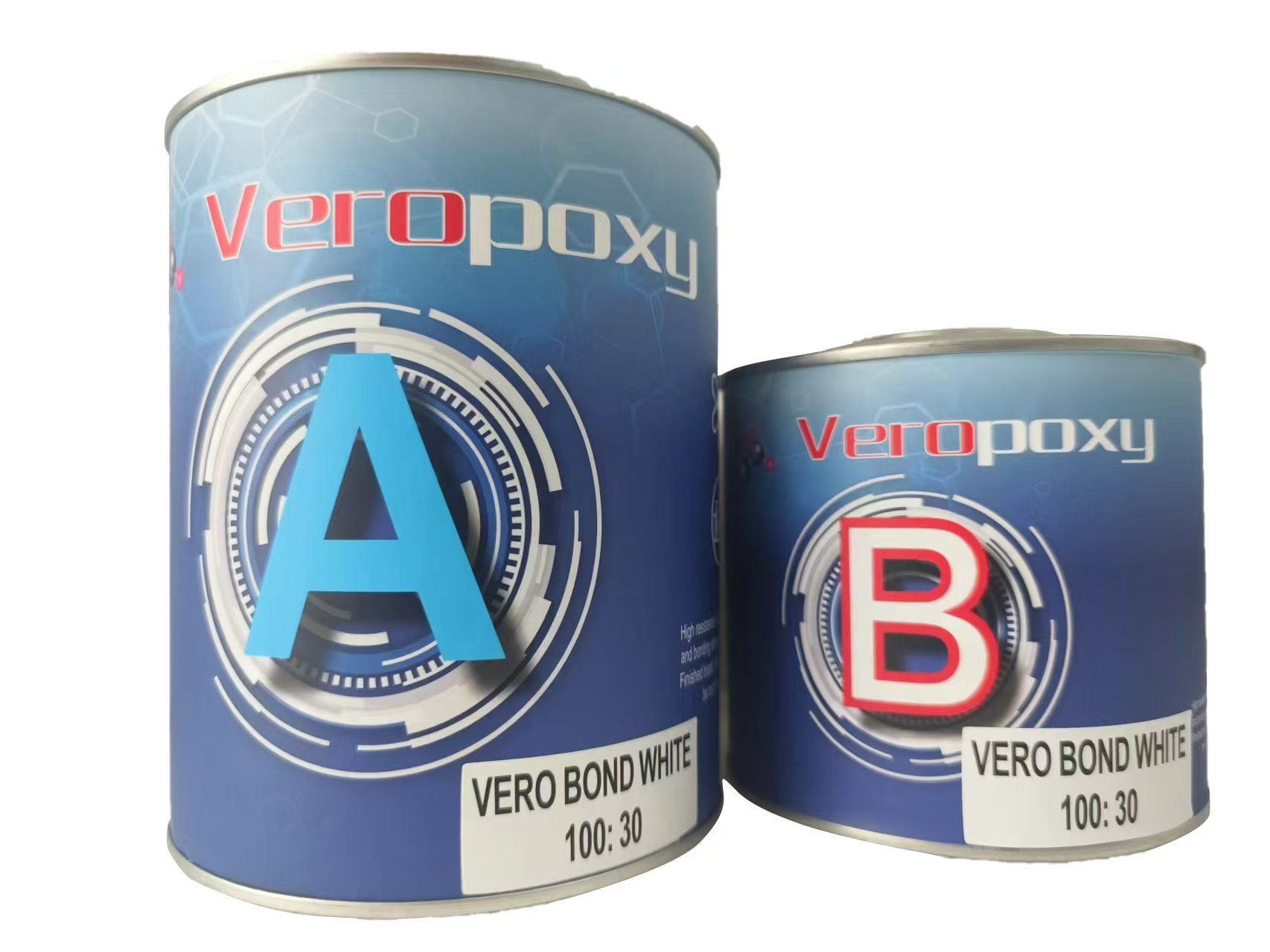

With its A and B two-component ratio (100:25), Vero Bond Epoxy resin has the best bonding effect. Although it guarantees the best bonding strength, the scientific ratio design of components A and B makes practical application more convenient. Particularly in the stone sector, it is appropriate for a range of materials since it can adapt to different complicated surroundings and preserve the bonding action for a long period.

Great Atthesion

High adherence of Vero Bond Epoxy resin is its main advantage. This resin guarantees a flawless mix on high-gloss materials like marble and granite since it can securely bond many surfaces, including polished surfaces. This guarantees dependable bonding on many stone surfaces for professional stone fabricators and builders, therefore preventing rework and waste resulting from adhesive failure.

robust resilience against strong weather

Vero Bond Epoxy resin exhibits unmatched environmental conditions-based weather resistance. This resin can keep its structural integrity and binding strength when it is subjected to low, high, or humidity as well as temperature. This makes it especially appropriate for outdoor stone projects including garden sculptures, outside wall decorations and other open-air amenities, thereby guaranteeing that the bonding effect will endure as good as new independent of weather conditions.

Flexible uses

Apart from granite and marble, Vero Bond Epoxy resin is quite appropriate for bonding various materials. This epoxy resin can offer robust bonding whether it is metal, glass, or ceramic, thereby extending its range of application. Vero Bond is a perfect fit for many different stone and associated sectors due to its adaptability for both indoor and outdoor use situations.

Possibilities and Characteristics

Excellent adhesion and strong bonding ability of Vero Bond Epoxy resin enable it to firmly join different materials, even smooth polished surfaces.

Its great weather resistance helps it to keep strong adhesion under demanding climatic conditions and will not lose viscosity owing of changes in the external environment.

Wide compatibility: With so many uses, this product is not only appropriate for stone but also may be bonded to other metals, ceramics and other materials.

Easy operation: The bonding action is more stable and operators may utilize it conveniently and fast by means of the percentage of A and B components.

Simple operation with notable influence

Using Vero Bond Epoxy resin comes really easily. Following directions, just equally mix the two components; then, apply them to the surface to be glued. Its quick curing properties help building professionals to finish the job quickly and increase work effectiveness. Projects involving significant scale of construction especially depend on this efficiency benefit.

Notes of caution

Use Vero Bond Epoxy resin carefully to keep the workplace adequately ventilated and to avoid direct touch with skin and eyes. Remaining adhesive should be sealed in time following usage to stop air from entering and resulting in cure failure. Simultaneously, combine strictly in line with the percentage to guarantee the best bonding effect.

Storage of epoxy resin

Ensuring the performance and purity of epoxy resin is absolutely vital while storage. Epoxy resin should first of all be kept in a cool, dry location free from direct sunshine and high temperature surroundings since too high temperature may hasten its curing process and influence the usage impact. Usually, the best storage temperature falls between 15℃ and 25℃.

Simultaneously, ensure the container is tightly shut to stop air and moisture from getting in and stop resin breakdown. Apart from that, the kept epoxy resin should be routinely tested to guarantee absence of stratification or precipitation. Should any anomalies arise, they should be addressed carefully to prevent influencing the subsequent use effect. Epoxy resin’s shelf life can be extended by reasonable storage conditions, so enabling always excellent performance when required.