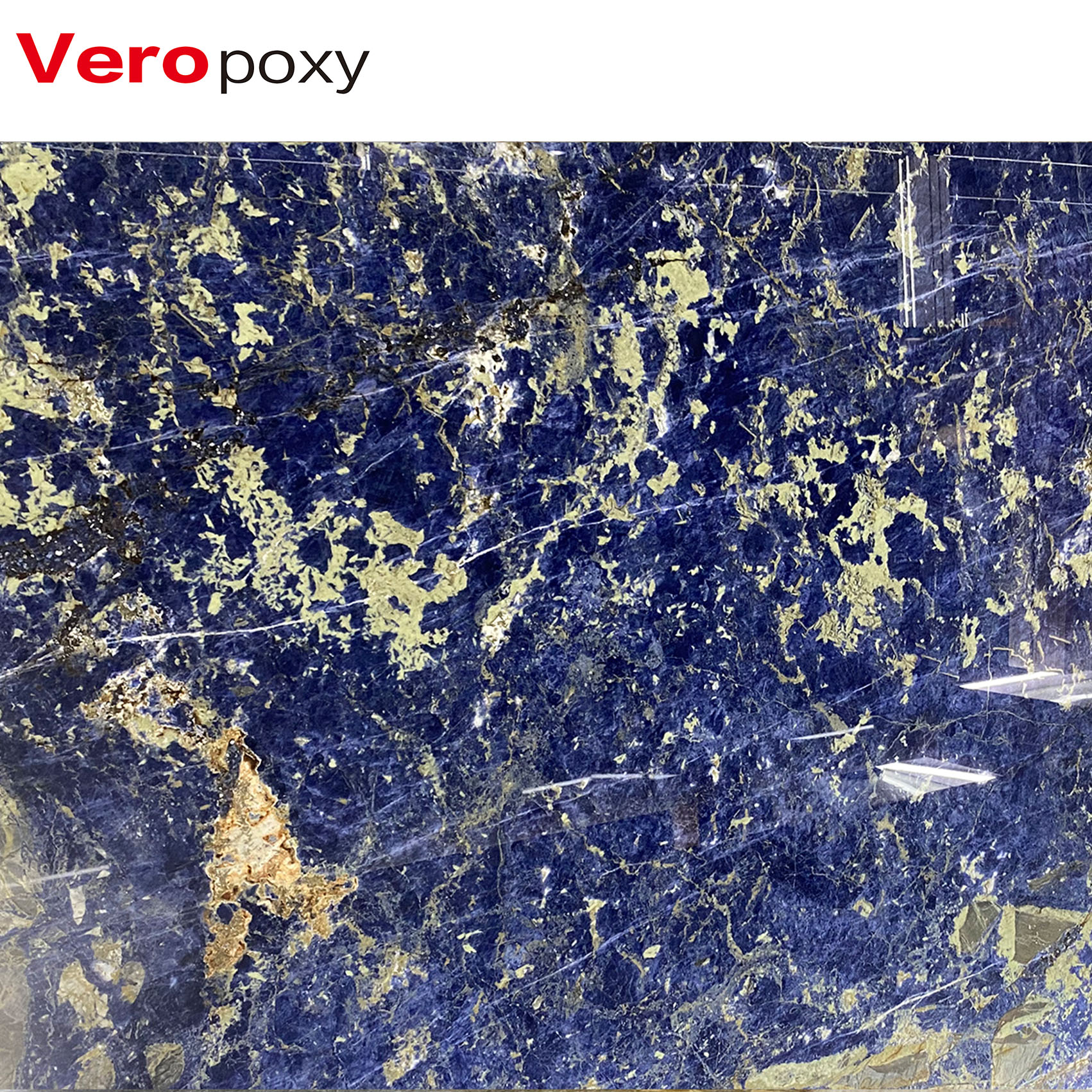

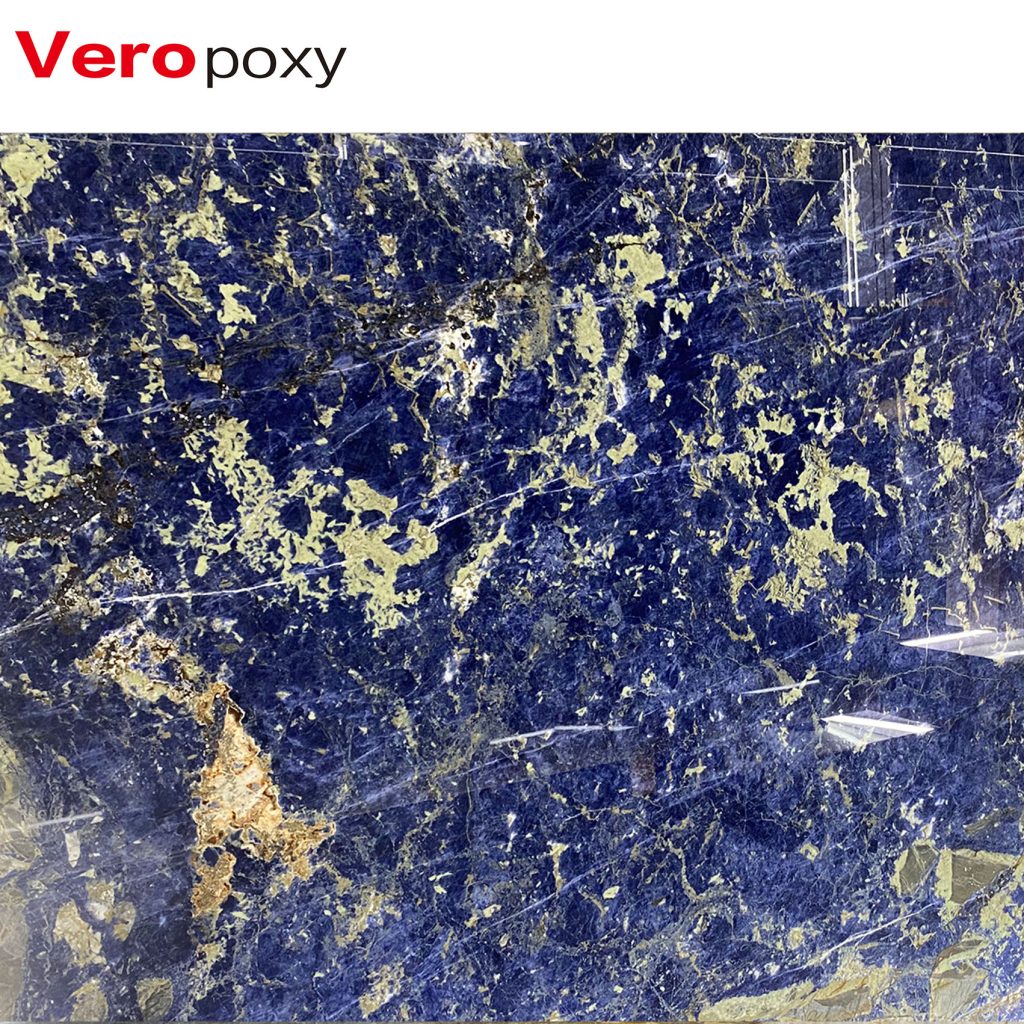

Epoxy for quartzite

- Feature: Epoxy Resin for Blue and Gold quartzite

- Applicable material: Blue and Gold quartzite

- Epoxy system code: 4090BF+D30M-BSFS

- Epoxy system ratio by weight: 100:30

- Curing effect: Forms a glossy and protective sealing layer

Overview

Epoxy resin is a high-performance material used in surface coating and restoration of quartzite slabs. It enhances the waterproof, anti-fouling, and anti-ultraviolet qualities of quartzite, while also preserving its natural sheen. Component A consists of filler, toughening agents, and epoxy resin, while Component B is a modified amine curing agent. Epoxy resin is widely used in homes, companies, and luxury hotels to maximize the use value of quartzite.

Product Description

Product Features:

| Feature | Epoxy Resin for Blue and Gold quartzite |

|---|---|

| Applicable material | Blue and Gold quartzite |

| Epoxy system code | 5099-Z+D30M-BS |

| Epoxy system ratio by weight | 100:30 |

| Curing effect | Forms a glossy and protective sealing layer |

| Durability | High stability and long-lasting after curing, good resistance to discoloration, low viscosity, strong bonding, minimal watermark effect |

| Ease of Use | Easy to mix and apply, no special tools required |

Epoxy resin repairs quartzite cracks and gaps

Epoxy resin is a very effective material for repairing quartzite cracks and gaps. It has excellent adhesion and wear resistance, and can penetrate into the tiny gaps of the cracks to form a solid repair layer. During the repair process, the crack area needs to be cleaned first to remove any dust and impurities. Then, apply epoxy resin evenly to the crack and use a scraper to smooth it out to ensure that it is flush with the quartzite surface. After curing, epoxy resin not only restores the appearance of quartzite, but also enhances its overall strength and durability, making quartzite more durable in daily use. This not only saves replacement costs, but also extends the service life of quartzite.

Epoxy resin is a two-component super strong adhesive, which belongs to the epoxy adhesive class and is suitable for bonding a variety of materials such as quartzite and granite. This product has extremely high adhesion and strong weather resistance, and is one of the strongest epoxy resin adhesives in the stone industry. Whether it is a rough surface or a smooth polished surface, it can firmly bond, providing a long-lasting and reliable guarantee for the combination of various materials.

The application steps of epoxy resin in stone processing are as follows:

First, place the large board on the glue repair trolley or glue repair line, and ensure that the surface to be sanded is facing up. For large boards with severe cracks, repairs are required and reinforcement may be used with steel bars, aluminum bars or plastic bars. Next, clean the surface to be sanded and ensure that it is dry and dust-free to remove any substances that may affect the adhesion of epoxy resin.

Then, choose a suitable fiber mesh according to the area of the large board. The size of the fiber mesh should be 60mm smaller than the length and width of the large board. When mixing epoxy resin glue, mix according to the proportion of A and B components on the instructions, and use a mixer to ensure uniform mixing. Scrape the prepared epoxy resin glue evenly on the surface of the stone and the fiber mesh, ensuring that the colloid completely covers the mesh.

Then, evenly sprinkle the quartzite sand that meets the requirements on the surface of the epoxy resin glue. The large board after sanding needs to be cured by natural drying or drying. After the epoxy resin glue on the sanding surface is completely dry, the board is collected to prevent sand particles from falling off and offset printing.

Add a plastic film between the sanding surface and the front of the slab to prevent the sand from rubbing against the front of the stone. Pack or stack the sanded slabs in turns. Finally, cut the sanded slabs that need to be processed, and use spacers to protect the front of the product from being scratched by sand.

These steps describe the use of epoxy resin in stone processing in detail, from preparation to final processing, ensuring that epoxy resin can be effectively used for stone repair and enhancement.

Precautions:

Use this product in a well-ventilated area.

Keep out of reach of children and pets.

Read the product manual carefully before use.

Packaging Specifications:

1 kg container

5 kg container

Shelf Life:

12 months when unopened.

Epoxy resin storage

The performance and use effect of epoxy resin depend critically on its storage method. Epoxy resin should first of all be kept dry, cool, away from direct sunshine and a hot surroundings. Usually, the perfect storage temperature falls between 15°C and 25°C). Furthermore ensure that the container is tightly sealed to stop air, moisture, and pollutants from entering and so prolonging its shelf life. Using committed sealed containers or original packing is a wise decision. Try not to mix several resin batches before use to prevent compromising the curing action.

Regular monitoring of the kept epoxy resin is also crucial to guarantee that it has not degraded or polluted. Immediately cease using it if you discover precipitation, discolouration, or odour. Epoxy resin should thus be avoided to store it in a cold environment as, in a low temperature environment it may get sticky or incompletely cured. Epoxy resin can also be quite protected by selecting a well-ventilated storage area free of touch with strong acids, strong bases and other chemicals.

Ultimately, epoxy resin has a limited shelf life and performance may suffer after expiration; so, regular inventory updating is necessary. Following these storage rules helps you to make sure your epoxy stays in best shape for use as required.