Epoxy resin for marble repair and reinforcement

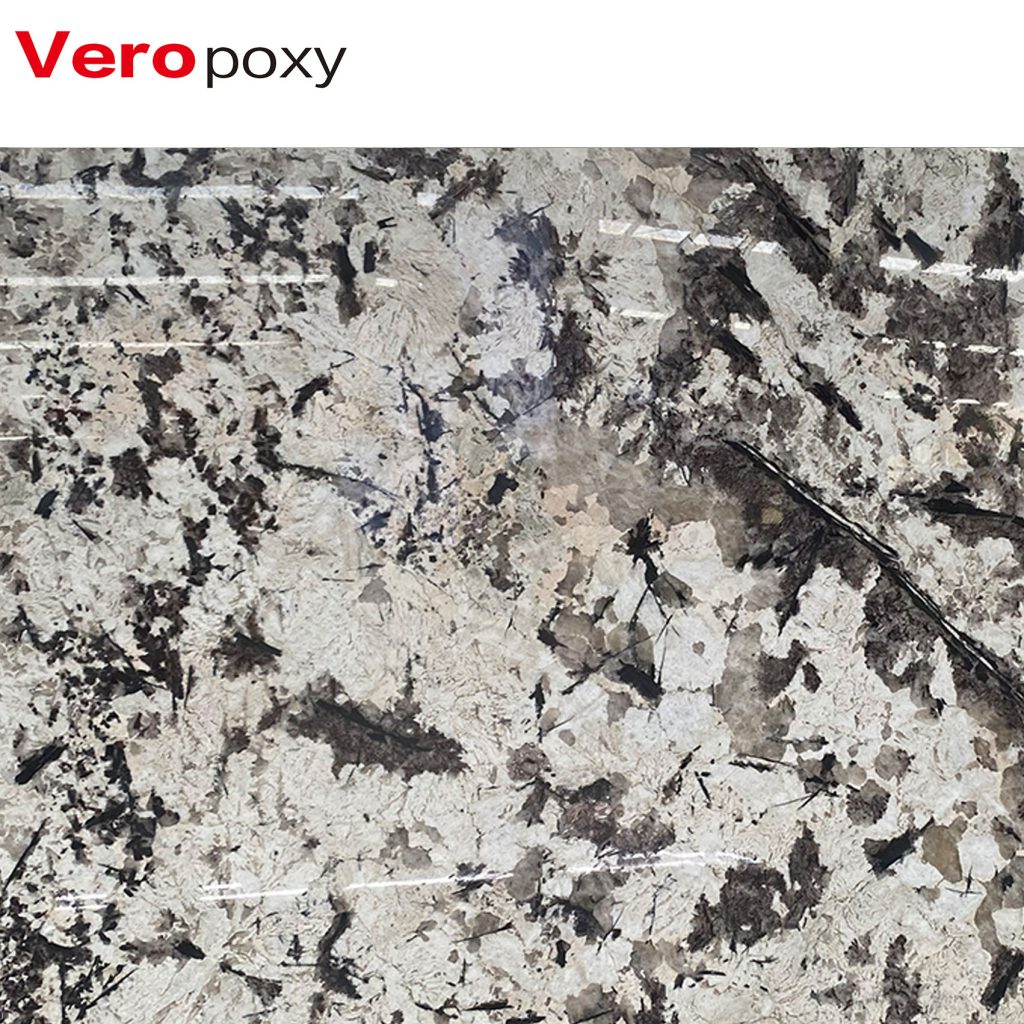

- Feature: Epoxy Resin for Black and Gray Marble

- Applicable material: Black and Gray Marble

- Epoxy system code: 4099+B25Q-KG

- Epoxy system ratio by weight: 100:25

- Curing effect: Forms a liquid sealing layer

Overview

Epoxy resin, a synthetic polymer with excellent bonding, chemical resistance, and mechanical strength, is commonly used as a binder in marble slabs to enhance structural integrity, durability, and permeability, ensuring its beauty and practicality.

Product Description

Describes epoxy resin

Excellent bonding qualities, chemical resistance, mechanical strength—all of which are synthetic polymer traits—epoxy resin Often employed as a binder to improve the structural integrity and durability of the stone in marble slabs is epoxy resin. Ensuring the beauty and practicality of the product during use, it can efficiently fill the fine cracks and holes on the surface of marble, give a smooth surface effect, and increase the permeability and wear resistance of marble, so guaranteeing its beauty and usefulness.

Product Features

| Feature | Epoxy Resin for Black and Gray Marble |

|---|---|

| Applicable material | Black and Gray Marble |

| Epoxy system code | 4099+B25Q-KG |

| Epoxy system ratio by weight | 100:25 |

| Curing effect | Forms a liquid sealing layer |

| Durability | High stability and long-lasting after curing, good yellowing resistance, low viscosity, strong bonding |

| Ease of Use | Easy to mix and apply, no special tools required |

Product Highlights

* Simple User Interface

Perfect texture, convenient 1:1 ratio, easy to use for both beginners and experts. No need to wear a mask when working.

* Safety First

Made of high-quality non-toxic ingredients, 100% safe for indoor and outdoor use, clear epoxy does not contain any harmful chemicals, reactions or fumes!

* Powerful UV Light

Self-leveling formula provides top-level UV protection coating experience powerful light and excellent gloss, guaranteed for lifetime use!

Steps for epoxy resin repair of marble

The steps of epoxy resin repair marble mainly include the following stages:

Surface pre-polishing:

The surface flatness of marble is poor after sawing, and pre-polishing can make the surface basically flat, and the concave and convex surface cannot exceed 0.20mm. This step is to ensure that the epoxy resin can effectively adhere to the surface and gaps of the stone to achieve the desired effect.

Cleaning and drying:

After grinding the stone surface, stone powder and abrasive mixture will remain. These dusts will hinder the combination of epoxy resin and stone. Therefore, it is necessary to use a brush with clean water or high-pressure water to remove dust. After cleaning, the board needs to be air-dried or naturally air-dried. If more thorough drying is required, tunnel or tower drying equipment can be used for drying, usually controlled at 45 to 55 degrees, and the time is about 120 minutes.

Laying epoxy resin, curing and polishing:

After the epoxy resin is heated and melted, it is evenly applied to the surface of the stone, and the thickness of the application is between 0.50mm and 1mm. During the leveling process, a certain amount of pressure should be applied to allow the resin to enter the gap. If it is a large plane, automated mechanical coating may be used.

After the stone is flattened with resin, it is sent to the drying container, and the container temperature is controlled at 30 to 40 degrees for about 120 minutes. At room temperature, the resin needs to be left still for about 24 hours to fully cure. After curing, the resin and the material are integrated into one, and the glue repair process is completed. After the marble is polished after glue repair, the mechanical strength is improved, and the color is more uniform and gorgeous.

Notes for application:

Usually employed with a curing agent, epoxy resin must be blended carefully according to guarantee the performance of the resultant product. Furthermore, the volatile organic compounds (VOCs) of epoxy resin could affect health; hence, one should pay close attention to ventilation and use protective gear while handling it.

Uses and effects of epoxy resin on marble slabs

Using marble slabs benefits and effects from epoxy resin in several ways. First of all, it can improve marble’s wear resistance and strength so increasing its durability in regular use. Furthermore, epoxy resin offers great waterproof qualities that can stop moisture from seeping in and lower the chance of marble discolouration or damage.

Second, while marble surface is being repaired, epoxy resin’s transparency helps it to retain natural lustre and look. It can also cover small flaws and cracks on the marble surface to enhance the general beauty. All things considered, epoxy resin not only enhances the performance of marble slabs but also increases their service life, therefore guaranteeing that they remain in good shape in many different surroundings.