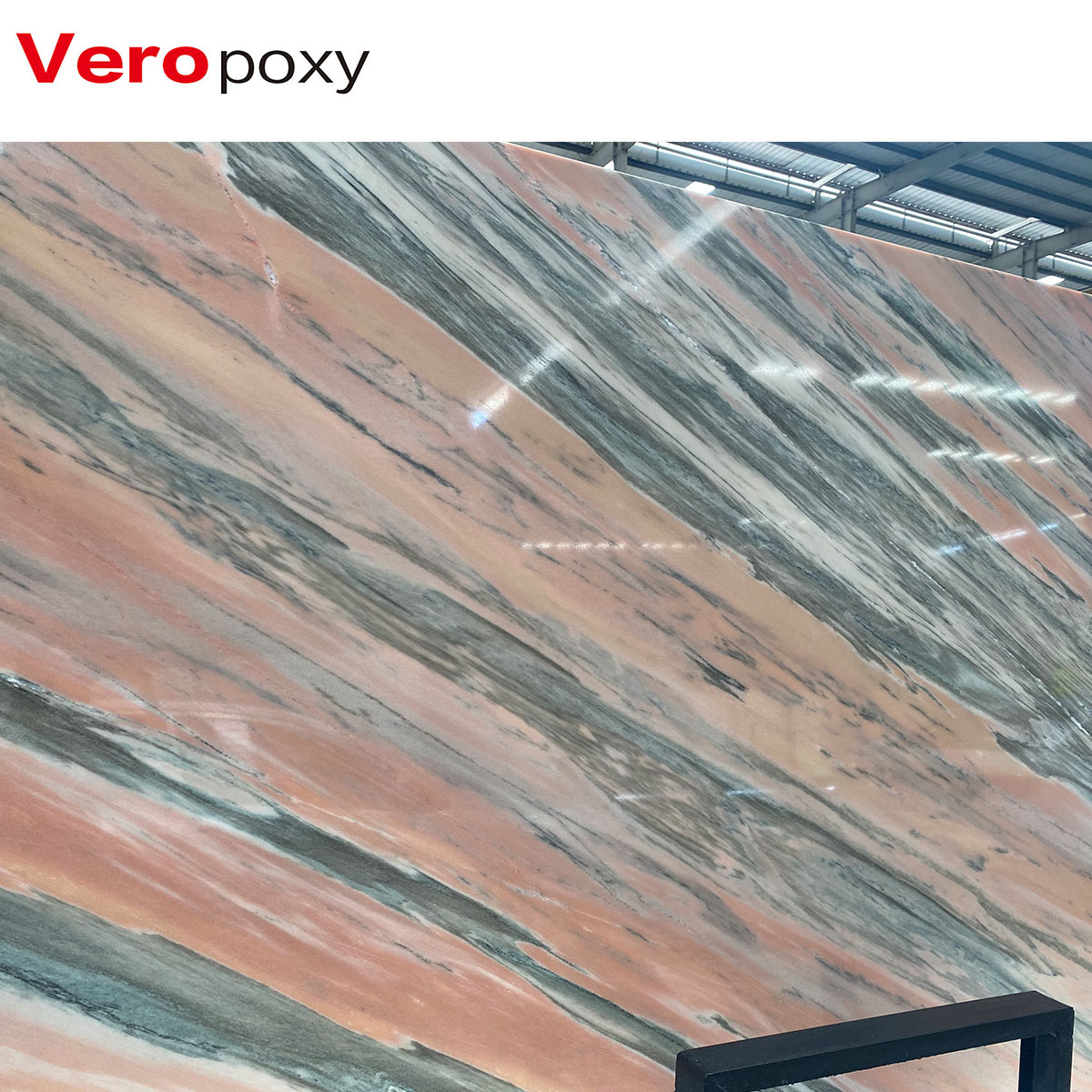

High Quality Epoxy Resin Epoxy Resin for Marble Slabs

- Feature: Epoxy Resin for Soft Marble

- Applicable material: White Soft Marble

- Epoxy system code: 5090-Z +D30M-BS

- Epoxy system ratio by weight: 100:30

- Curing effect: Forms a liquid sealing layer

Overview

Epoxy resin, a synthetic resin with excellent adhesion and chemical resistance, is ideal for marble splicing due to its strength, toughness, and durability in high-pressure, high-temperature, and humid environments.

Product Description

What is epoxy resin?

Epoxy resin is a synthetic resin made of epoxy compounds and hardeners, which has excellent adhesion and chemical resistance. Compared with traditional glue or other adhesives, epoxy resin has obvious advantages in strength, toughness and durability. This makes it an ideal choice for marble splicing, and it can maintain stable performance under high pressure, high temperature and humid environments.

Product features:

| Feature | Epoxy Resin for soft white Marble |

|---|---|

| Applicable material | Soft White Marble |

| Epoxy system code | 5099-Z +D30M-BS |

| Epoxy system ratio by weight | 100:30 |

| Curing effect | Forms a liquid sealing layer |

| Durability | High stability and long-lasting after curing, good yellowing resistance, low viscosity, strong Bonding |

| Ease of Use | Easy to mix and apply, no special tools required |

Application of epoxy resin in marble splicing

1. Possibility of seamless splicing

During the installation process of marble, traditional adhesives often fail to achieve the ideal seamless effect, and are prone to leaving gaps and flaws. Epoxy resin can easily achieve seamless splicing. Its excellent fluidity enables it to fill tiny gaps and form a solid bonding surface, thereby ensuring the overall beauty and structural stability of the marble.

2. Improve the durability of marble

Epoxy resin can not only achieve seamless splicing, but also improve the durability of marble. Due to its excellent water resistance and chemical resistance, marble bonded with epoxy resin can still maintain its original gloss and color after long-term use. This is especially important for kitchen countertops, bathrooms, and other humid environments.

3. Easy construction

The process of using epoxy resin for marble splicing is relatively simple. Construction workers only need to mix epoxy resin and hardener in proportion, then apply it to the marble surface, and then put the parts to be bonded together. The fast curing time and good fluidity greatly improve the construction efficiency, saving time and labor costs.

Characteristics of epoxy resin

1. Excellent adhesion

The strong adhesion of epoxy resin enables it to firmly bond various materials, including marble, glass, metal, etc. This feature ensures that there will be no falling off or breaking at the junction of marble and other materials.

2. Strong weather resistance

Epoxy resin has excellent weather resistance and can resist the erosion of ultraviolet rays, avoiding color fading and performance degradation caused by sunlight. This allows marble bonded with epoxy resin to be used for a long time in outdoor environments.

3. Environmentally friendly and non-toxic

Modern epoxy resin products pay more and more attention to environmental protection in the manufacturing process. Veropoxy has launched low-volatile organic compound (VOC) epoxy resin to ensure that no harmful gases are released during use, which is friendly to human health and the environment.

Storage of epoxy resin

Epoxy resin should be stored in a cool, dry, and well-ventilated area at 15-25℃, with humidity levels between 40%-60%. Keep it in corrosion-resistant, tightly sealed containers to prevent exposure to moisture, air, and contaminants.

The storage area should display clear safety signs for flammability, toxicity, and corrosion. As epoxy resin is flammable, store it away from fire sources and flammable materials, and avoid direct sunlight to preserve its quality. Note its shelf life and use within this period. Once opened, reseal the container promptly to prevent moisture absorption or premature curing.