Liquid Epoxy Resin for Epoxy Floor Marble

- Feature: Epoxy Resin for white Marble

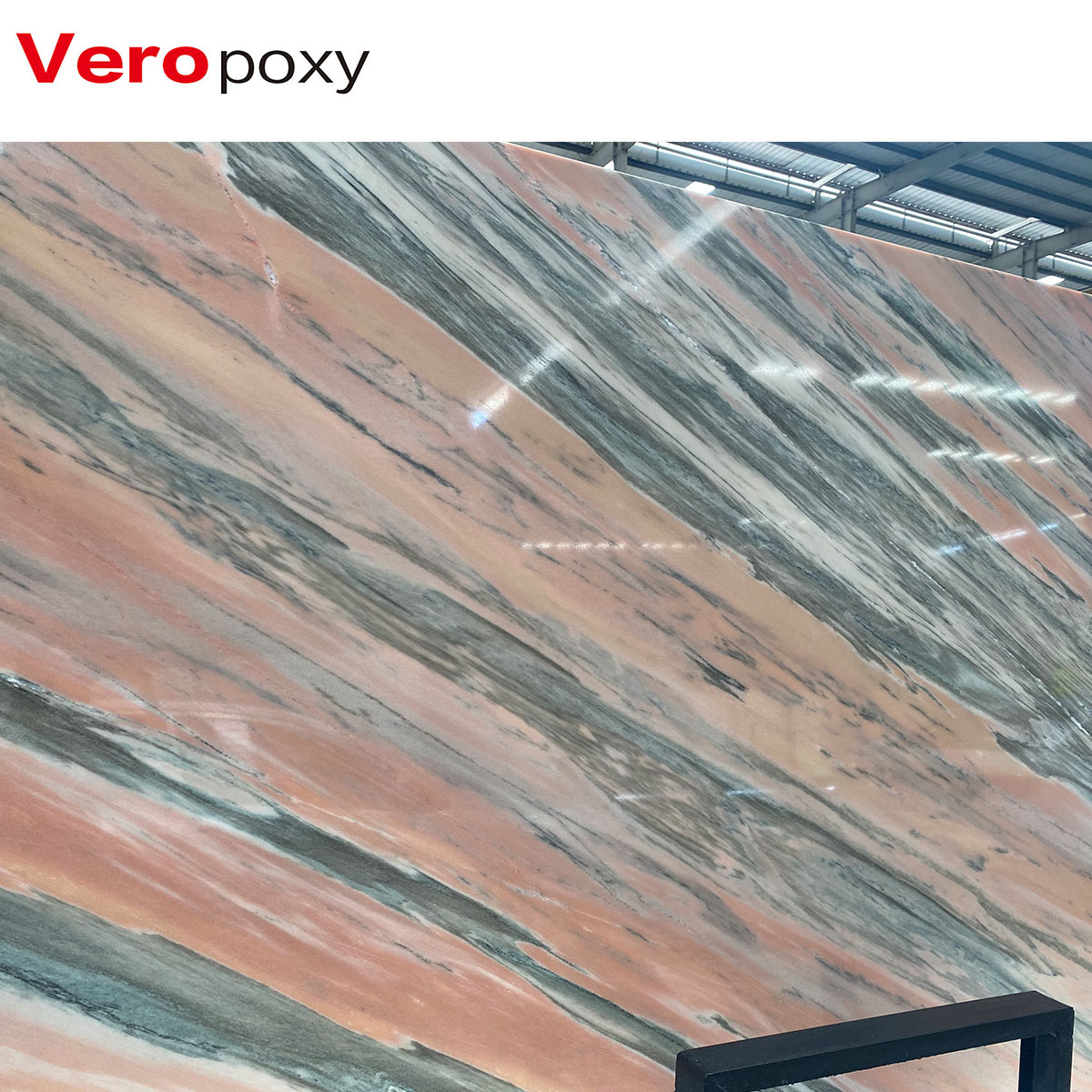

- Applicable material: Calacatte , Stuario, Carrara White

- Epoxy system code: 5099-YC +D30M-BS

- Epoxy system ratio by weight: 100:30

- Curing effect: Forms a liquid sealing layer

Overview

This product is a two-component adhesive, consisting of epoxy resin and a modified amine curing agent. It is popular for marble slabs due to its durability, adherence, and ability to close small cracks, improving wear resistance and anti-fouling properties. Epoxy is used in homes, businesses, and luxury hotels to maximize marble usage value.

Product Description

Product Introduction

This product is a two-component adhesive. Component A is composed of epoxy resin, toughening agent, and filler, and its appearance is a white viscous thixotropic liquid; Component B is a modified amine curing agent, which is composed of accelerators, fillers, etc., and its appearance is a blue viscous thixotropic liquid.

Epoxy resin’s great adherence and durability have drawn more and more interest for use in marble slabs. Epoxy is a high-performance material that can efficiently close the small cracks and defects on the surface of marble, so improving the wear resistance and anti-fouling capacity in addition to the appearance.

Epoxy is frequently used for surface coating and repair in the production of marble slabs, therefore increasing marble’s waterproof, anti-fouling, anti-ultraviolet properties. Moreover, epoxy resin’s transparency helps it to preserve marble’s inherent gloss. It is extensively utilized in homes, businesses, luxury hotels and other venues, and has grown to be a major decision to maximize the usage value of marble.

Product features:

| Feature | Epoxy Resin for white Marble |

| Applicable material | Calacatte , Stuario, Carrara White |

| Epoxy system code | 5099-YC +D30M-BS |

| Epoxy system ratio by weight | 100:30 |

| Curing effect | Forms a liquid sealing layer |

| Durability | High stability and long-lasting after curing,good yellowing resistance , low viscosity , strong Bonding |

| Ease of Use | Easy to mix and apply, no special tools required |

Product Information

| Product Features | Details |

|---|---|

| Origin | China |

| Main Raw Material | Epoxy Resin |

| Application | Construction |

| Alternative Name | Epoxy Adhesive |

| Classification | Two-Component Adhesive |

| Brand | Veropoxy |

| Type of Adhesive | Epoxy Resin |

| Usage | Coating and sealing of rough surfaces |

| Features | – Cures 100% at room temperature or with heat.<br>- High gloss, transparent, impact-resistant, waterproof, self-leveling.<br>- Does not yellow when exposed to sunlight over time.<br>- Easy to operate; excellent air release properties. |

| Early Development of Performance and Physical Quality | – No ripples, smooth surface, odorless, eco-friendly, non-toxic, waterproof, etc.<br>- Easy to repair and clean. |

Method of operation

1.Weigh glue A and glue B using the specified weight ratio; pour into the ready clean container; twist the mixture clockwise around the container wall to mix completely; let it stand for three to five minutes before use.

2. Use glue in line with the useful time and quantity to minimize waste. Please heat glue A to 30℃ when the temperature is less than 15℃ before combining with glue B; the glue must be covered after use to prevent moisture absorption and rejection. The glue will thicken at low temperatures.

3.The surface of the cured mixture will collect air moisture and develop a layer of white mist on top when the relative humidity is higher than 85%. For room temperature curing, then, the relative humidity above 85% is not appropriate. One is advised to use heated cure.

Precautions:

Use this product in a well-ventilated area.

Keep out of reach of children and pets.

Read the product manual carefully before use.

Storage Conditions:

Store in a cool, dry, and well-ventilated area, away from fire and high temperatures.

With this introduction, you can fully understand the product features and usage methods of the Epoxy Resin Sealant for Marble. We are committed to providing high-quality products to meet your needs for the maintenance and repair of Marble.