Manufacturers wholesale hot selling two-component sealant granite glue epoxy resin glue

- Feature: Epoxy Resin for Granite

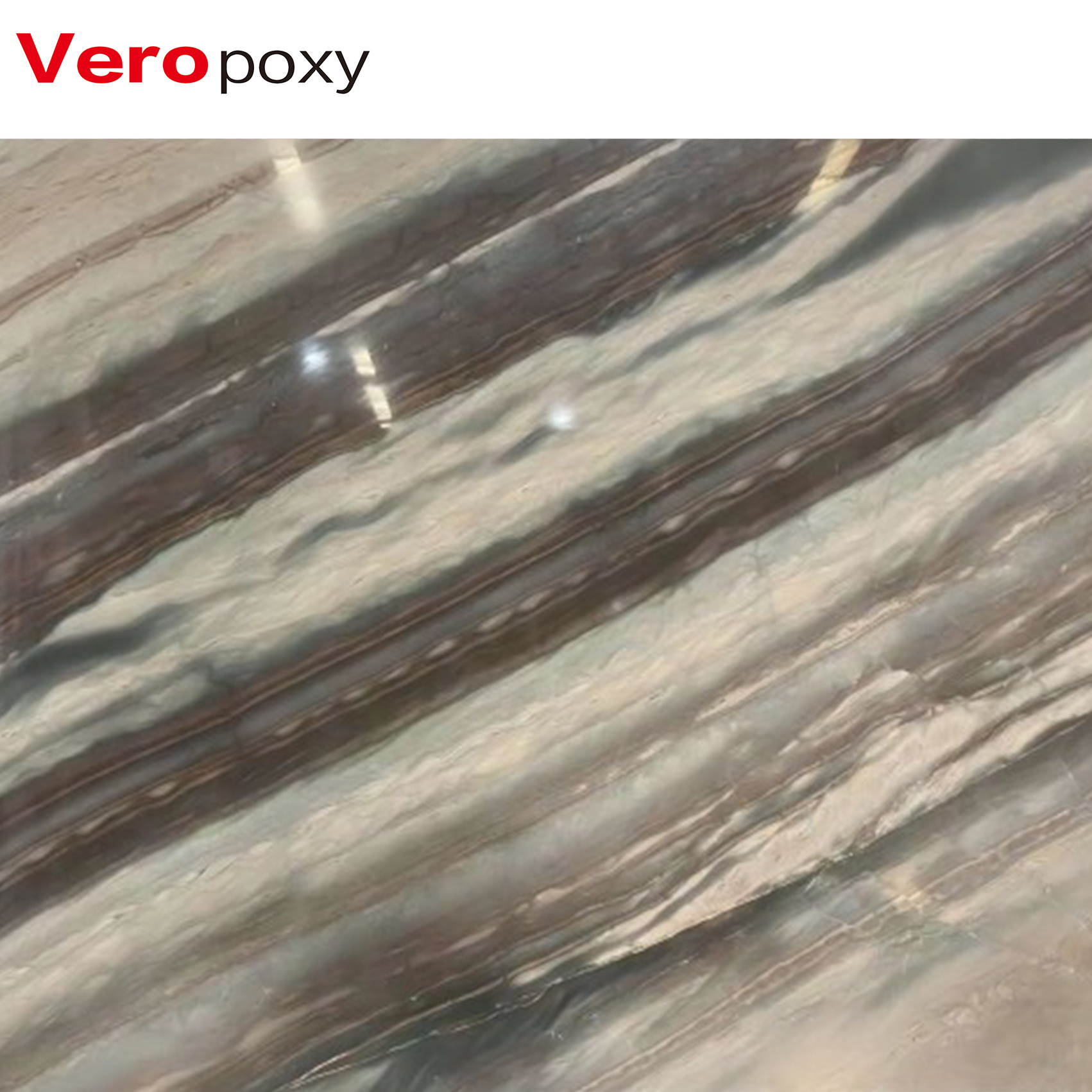

- Applicable material: Okapi white , Pandora , Amazonite Blue

- Epoxy system code: 5099+B25Q-KG

- Epoxy system ratio by weight: 100:25

- Curing effect: Forms a liquid sealing layer

Overview

Epoxy resin, also known as artificial resin or resin glue, is a crucial thermosetting plastic used in adhesives and stone construction. Veropoxy epoxy adhesive is a two-component, fast curing adhesive with excellent aging, moisture, electrical insulation, elastic impact resistance, and high breakdown voltage. It is suitable for bonding and sealing granite, stone, and buildings, and is increasingly used in decoration in homes, hotels, and public halls.

Product Description

Epoxy resin, also known as artificial resin, artificial resin, resin glue, etc., is a very important thermosetting plastic, widely used in adhesives, stone construction, etc., and is a high molecular polymer. Veropoxy epoxy adhesive is a two-component, room temperature curing fast curing epoxy resin adhesive. It has the characteristics of fast curing, and has better flexibility than ordinary epoxy adhesives and is not easy to break.

It has excellent aging resistance, moisture resistance, electrical insulation, elastic impact resistance and high breakdown voltage. It is suitable for various bonding and sealing of granite, stone, and buildings.

As a new material in the decoration market, it is widely used in the decoration of homes, hotels and public halls.

Product Features:

| Feature | Epoxy Resin for Granite |

| Applicable material | Okapi white , Pandora , Amazonite Blue , |

| Epoxy system code | 5099+B25Q-KG |

| Epoxy system ratio by weight | 100:25 |

| Curing effect | Forms a liquid sealing layer |

| Durability | High stability and long-lasting after curing,good yellowing resistance , low viscosity , strong Bonding

Low watermark effection . |

| Ease of Use | Easy to mix and apply, no special tools required |

Products Characteristics

Our epoxy resin has extremely high bonding strength, which will help to guarantee that damages and fissures in granite slabs are tightly healed. This epoxy resin may offer strong bonding regardless of the size of the damage or the little gap.

Epoxy glue is quite resistant to many different chemicals, which helps it to effectively guard granite surfaces from erosion in settings like chemical laboratories and industrial factories.

Good water-proof performance of the epoxy resin covering helps to prevent moisture from seeping into the granite’s interior, so avoiding damage resulting from moisture.

Usually including comprehensive directions for use, epoxy resin solutions allow consumers to mix and apply with simple procedures. Its flexibility and fluidity help it to cover uneven surfaces and fissures.

Epoxy resin can be used in a range of hues to either accentuate or match granite’s inherent beauty. Its gloss and transparency are adjusted to produce the intended visual impact.

Other properties

Origin: China

Main raw material: epoxy resin

Use: Construction

Name: Epoxy Adhesive

Classification: Two-component Adhesive

Brand: Veropoxy

Adhesive type: Resin epoxy resin

Application: Rough surface coating and sealing

Advantages of granite slabs’ epoxy resin application

Granite slabs can be repaired and protected with epoxy in three major ways. First, epoxy glue guarantees the lifetime of the repair or installation by having very great adhesion and securely bonding to the granite surface.Second, epoxy resin is fit for many demanding conditions and has great chemical corrosion resistance, so resisting the erosion of acids, alkalis, and salts.

Furthermore, the protective coating created by epoxy resin can considerably stop moisture absorption and increase granite slabs’ service lifetime.

Excellent physical characteristics of epoxy resin include great strength, great hardness and strong wear resistance. These qualities give the rebuilt granite surface increased resistance to daily use impacts and scratches as well as durability.

Regarding building, epoxy resin provides a straightforward construction technique, fast curing speed, quick availability, and shortens the building cycle.

With high bonding strength and rather low colloid curing shrinkage, epoxy resin may finally undertake cross-linking reactions with different kinds of curing agents to produce polymers with a three-dimensional network structure, so performing well in terms of physical attributes. Low, the molecular weight is suitable, the viscosity is changeable, the wettability and permeability are good; the curing time is quite under control.

Directions

To guarantee the granite surface is free of dust, oil and moisture, clean it.

Mix components “A” and “B” following directions and well stir.

Apply the epoxy glue equally on the granite surface with a brush or scraper.

Allow the epoxy resin to cure in a suitable atmosphere for the period advised by the product instructions.

Sand and polish as necessary to get the best results once treatment has cured.

Measures

Wear suitable protective gear including gloves, goggles, and masks while using epoxy resin.

Make sure the workplace is properly vented to prevent breathing dangerous fumes.

Store unused epoxy resin correctly following package directions; stay away from direct sunshine and high heat.