Marble is a timeless material, celebrated for its elegance and versatility. Like any natural stone, though, it is not impervious to environmental influences or time. One such element that can ruin marble’s appearance over time and cause fading, discolouration, and surface damage is UV radiation. Many times used as a protective layer, epoxy resin coatings help to offset these effects. How successful, though, are these coatings against UV radiation?

Examining their strengths, limits, and useful applications, this article investigates how epoxy coatings might help to shield marble surfaces from UV radiation. Let’s explore the science underlying UV resistance and how epoxy combines with marble to maintain its beauty under sunlight.

Understanding UV Radiation and Its Impact on Marble

One of the components of sunlight, UV radiation can be quite destructive to natural materials including marble. UV contact causes damage including:

1.Color Fading

Particularly in lighter-colored varieties, Marble’s natural colours can fade under extended UV exposure.

2.Surface Degradation

Marble surfaces’ structural integrity might be compromised by UV rays, which results in rough texture and micro-cracks.

3.Increased Porosity

Marble may become more porous from constant UV exposure, which would make it more prone to staining and water absorption.

These problems make protecting marble surfaces—especially those used outdoors or in places with lots of sunlight—especially important.

The Role of Epoxy Coatings

Commonly used synthetic polymer for surface sealing and protection is epoxy resin. Applied to marble, it creates a transparent, strong layer with many advantages:

1.Surface Protection

Epoxy guards marble against stains, moisture, and physical damage.

2.Aesthetic Enhancement

It accentuates Marble’s natural veining and colour, so producing a glossy, polished look.

3.UV Resistance

UV stabilisers meant to lessen the effect of sunlight on the covered surface are part of some epoxy formulations.

Not all epoxy coatings, meanwhile, are made equal and their UV radiation resistance varies.

How Epoxy Interacts with UV Radiation

Epoxy resin lacks natural UV-resistance. Under continuous UV light, standard epoxy coatings often yellow, crack, or lose their clarity. Manufacturers sometimes include UV stabilisers or inhibitors into epoxy formulations to raise UV resistance. These compounds function through:

Absorbing UV Rays

UV stabilisers stop damaging rays from getting to the marble surface by absorbing them and dissipating them as heat.

Inhibiting Photo-Degradation

UV blockers reduce the chemical reactions that under sunlight cause epoxy to break down.

Despite these enhancements, even the best UV-resistant epoxy coatings may not completely block all UV radiation. Extended exposure over time can still cause slight discolouration or diminished clarity.

Advantages of Using UV-Resistant Epoxy on Marble

Prolonged Longevity

By reducing sun damage, UV-resistant epoxy prolongs the life of marble surfaces.

Preserved Aesthetics

It keeps the marble’s original colour and finish, so preventing yellowing or fading.

Versatile Applications

Outdoor projects including patios, poolside areas, and garden sculptures call for UV-resistant epoxy.

Enhanced Durability

Epoxy coatings guard against scratches, stains, and moisture intrusion in addition to UV protection.

Limitations of Epoxy Coatings Against UV

Incomplete UV Blocking

UV-resistant epoxy lessens the effects of sunlight, but it does not completely eliminate them.

Potential Yellowing

Especially in strong sunlight, even advanced formulations may gradually acquire a faint yellow tint.

Maintenance Requirements

Epoxy coatings may have to be routinely reapplied to remain effective, particularly in high-exposure areas.

Cost

High-quality UV-resistant epoxy can be costly, which raises the whole marble installation and maintenance expenses.

Practical Tips for Protecting Marble with Epoxy Coatings

Choose the Right Epoxy

Choose UV-resistant epoxy compositions with track record in outdoor projects.

Apply Correctly

To get an even, long-lasting coating, guarantee correct surface preparation and professional application.

Combine with Other Protective Measures

On marble surfaces, cover direct sunlight with awnings, curtains, or UV-filtering glass.

Regular Maintenance

Periodically check the epoxy coating and reapply as necessary to keep it protective.

Epoxy coatings can significantly enhance the durability and appearance of marble surfaces, providing a layer of protection against UV radiation. Although UV-resistant epoxy formulations essentially reduce fading, discolouration, and surface damage, they are not totally impervious to sunlight.

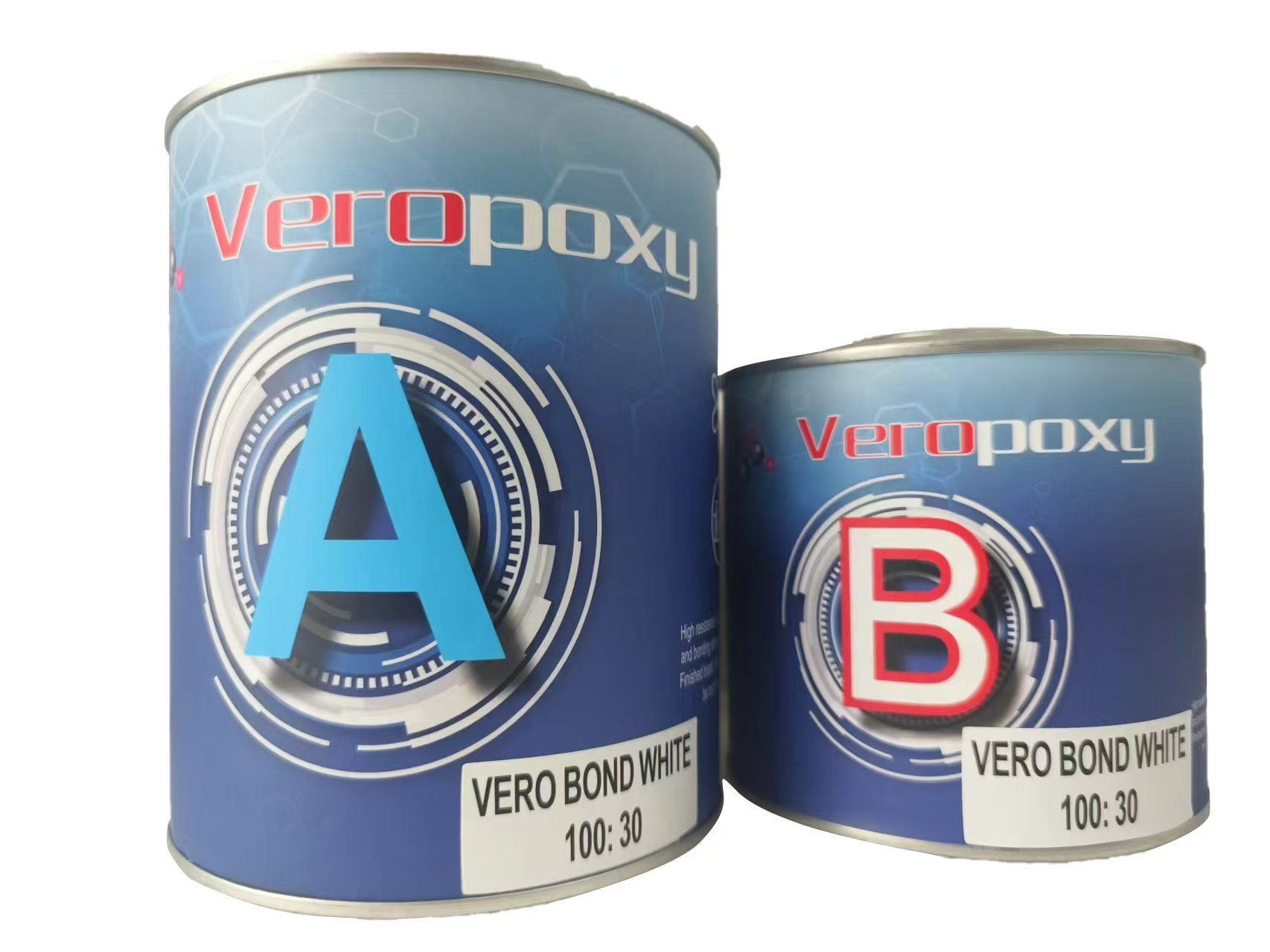

Epoxy resin

For homeowners and designers seeking to preserve the beauty of marble in sunny environments, a high-quality UV-resistant epoxy coating is an excellent investment. It guarantees that marble maintains its timeless elegance for years to come when combined with appropriate maintenance and other protective steps.

Post time: 11 月-22-2024