Marble, known for its beauty and elegance, has long been a favorite choice for luxury interiors and architectural features. Marble does, however, have natural flaws including brittleness and sensitivity to stains and scratches notwithstanding its outward beauty. Now let me introduce epoxy resin, a transforming substance rising in popularity for extending the lifetime of marble surfaces. But precisely what is the science underlying epoxy resin for marble, and how does it improve the structural integrity of the stone? Let’s investigate the amazing interaction between these two materials and learn how epoxy resin helps marble to remain beautiful, strong, and resilient for years.

Epoxy Resin in Marble

The Composition and Function of Epoxy Resin for Marble

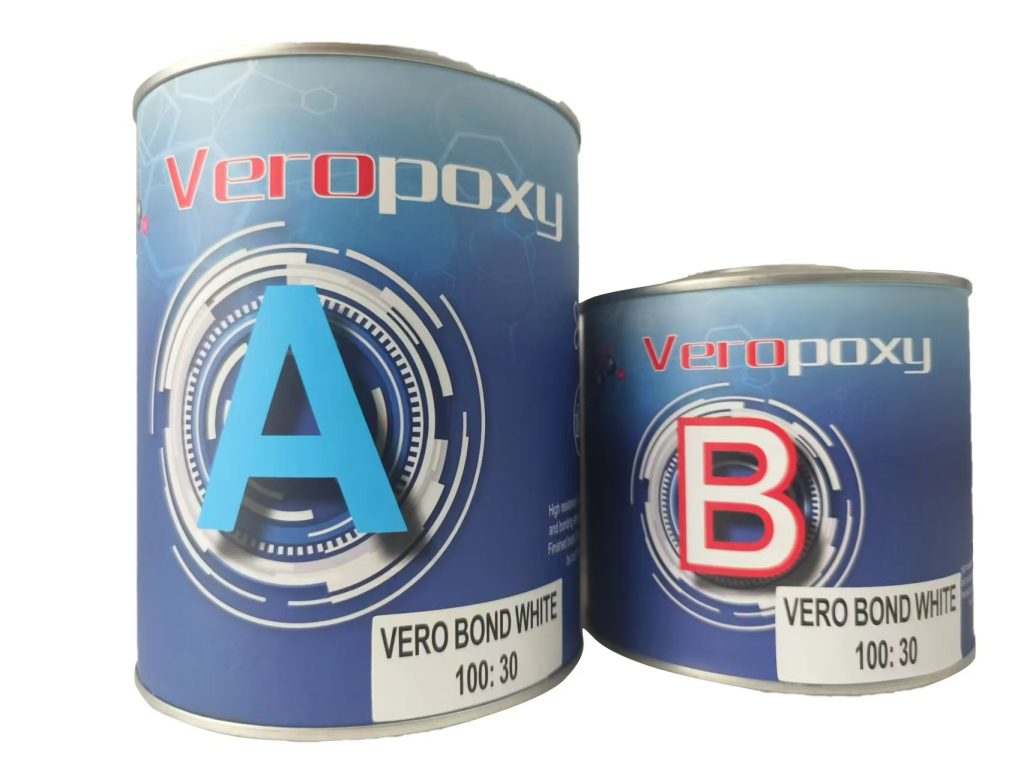

Epoxy resin is a two-part mixture consisting of resin and a hardener. These elements interact chemically to transform the liquid mixture into a solid, plastic-like material. By producing a strong and durable surface, this cured epoxy resin improves the structural stability of materials it bonds with—including marble. Marble’s general integrity is reinforced in addition to preventing cracks and chips by epoxy resin forming a barrier.

When applied to marble, epoxy resin seeps into the stone’s natural pores and fills tiny fractures and imperfections. This bond creates a solid matrix that not only strengthens weak areas of the marble but also offers a more smooth and durable surface. This produces a surface more suited to manage environmental variables like humidity and temperature swings, which might otherwise weaken the marble over time.

Enhancing Hardness and Reducing Brittleness

One of the most beneficial aspects of using epoxy resin for marble is its ability to increase the stone’s hardness. Marble is a rather soft stone, thus it is easily damaged from impacts and scratched. Once applied and cured, epoxy resin greatly increases the hardness of the marble, so enabling it to resist more pressure and reduce damage risk. For high-use areas like counters and flooring, where the stone might otherwise wear down rapidly, epoxy resin for marble is especially valuable because of its added durability.

The infusion of epoxy resin also reduces the brittleness of marble by creating a flexible layer that can absorb minor impacts without cracking. Marble installations in areas with lots of foot traffic or regular use will find this function especially helpful since the resin layer absorbs and distributes energy from impacts. Epoxy resin for marble functions essentially as a “shock absorber,” stopping cracks and fractures from spreading over the stone.

Improving Resistance to Environmental Factors

Marble is susceptible to environmental factors like temperature changes, moisture, and chemical exposure, which can cause surface damage and, over time, degrade the stone’s structural integrity. Epoxy resin for marble serves as a barrier protecting the stone from these elements, so preserving its strength and appearance for more extended periods of time.

For example, in humid conditions, marble can absorb moisture, leading to a weakening of the stone’s bonds and, potentially, the development of surface stains. Forming a water-resistant layer, epoxy resin guards the stone from such damage by stopping moisture intrusion. For marble surfaces in kitchens and bathrooms, where liquid exposure is regular, this water-resistant quality is also helpful. Epoxy resin for marble increases the lifetime of the stone by stopping water absorption, so improving its durability.

Boosting Marble’s Load-Bearing Capacity

Marble is often chosen for its aesthetic value, but it may not always be suitable for heavy-duty applications without reinforcement. Epoxy resin for marble gives the required strength to manage more weight. The resin strengthens the internal structure by bonding with the marble, so spreading weight more fairly over the stone. This makes epoxy-treated marble a great choice for areas needing extra durability, such flooring in commercial spaces or big kitchen islands that might bear great weight.

The load-bearing enhancement is particularly crucial for large marble installations, where weight distribution can become an issue. Epoxy resin for marble produces a cohesive and strong layer that lowers the possibility of cracks developing under heavy weights, so extending the lifetime of the installation and maintaining low maintenance costs.

Adding Gloss and Aesthetic Appeal

In addition to structural benefits, epoxy resin for marble enhances the stone’s aesthetic qualities. Epoxy resin develops a high-gloss, polished surface when cured that highlights marble’s inherent colours and patterns. Along with improving the stone’s look, this shiny layer helps guard it from dulling over time and from scratches.

The application of epoxy resin for marble creates a uniform surface that reduces the visual impact of any existing imperfections or inconsistencies in the stone. Epoxy resin is a common choice for high-traffic areas in hotels, restaurants, and luxury homes since this extra polish and protection helps marble installations to keep their beauty even with frequent use.

Epoxy resin

Epoxy resin for marble is a game-changer for improving the structural integrity, resilience, and visual appeal of the stone—not only a protective layer. Epoxy resin strengthens weak points and fills in natural pores to turn marble into a low-maintenance, durable surface able of withstanding daily wear and environmental elements. This bonding quality guarantees that marble installations can meet the needs of contemporary environments without compromising elegance or demanding frequent repairs.

It is obvious that epoxy resin has great potential to prolong the life and beauty of marble surfaces as we keep developing new uses for it. Epoxy resin is a great friend in maintaining the beauty and strength of marble whether in kitchens, businesses, or decorative projects, so guaranteeing that it will always be a timeless choice for both architects and design aficionados.

Post time: 11 月-08-2024