Travertine, a naturally porous and aesthetically rich stone, has found its place in numerous applications, from building facades to countertops and tiles. Travertine’s softness and wear-ability create some difficulties even with its beauty. Using epoxy resin as a bonding agent provides both structural integrity and long-term durability, thus it has become rather popular recently. Regarding adhesive strength, though, how does epoxy resin fare on travertine? The science behind this link is investigated in this paper together with how epoxy resin interacts with the special surface of travertine and the variables affecting its adhesive strength.

Understanding the Unique Nature of Travertine

Travertine is a sedimentary rock that forms in natural springs, often with visible holes or voids, which gives it a distinctive appearance. Although its natural look is much sought after in interior design, its porous structure can occasionally weaken the stone, increasing its susceptibility to cracking, chipping, and other types of damage. Travertine’s high calcium concentration and sensitivity to moisture and chemicals also provide difficulties for long term integrity maintenance.

To overcome these challenges, various methods of strengthening travertine have been developed, with epoxy resin emerging as one of the most effective solutions. Ideal bonding agent for travertine surfaces is epoxy resin, a synthetic material well-known for its great chemical resistance, durability, and adhesive strength.

How Epoxy Resin Works with Travertine

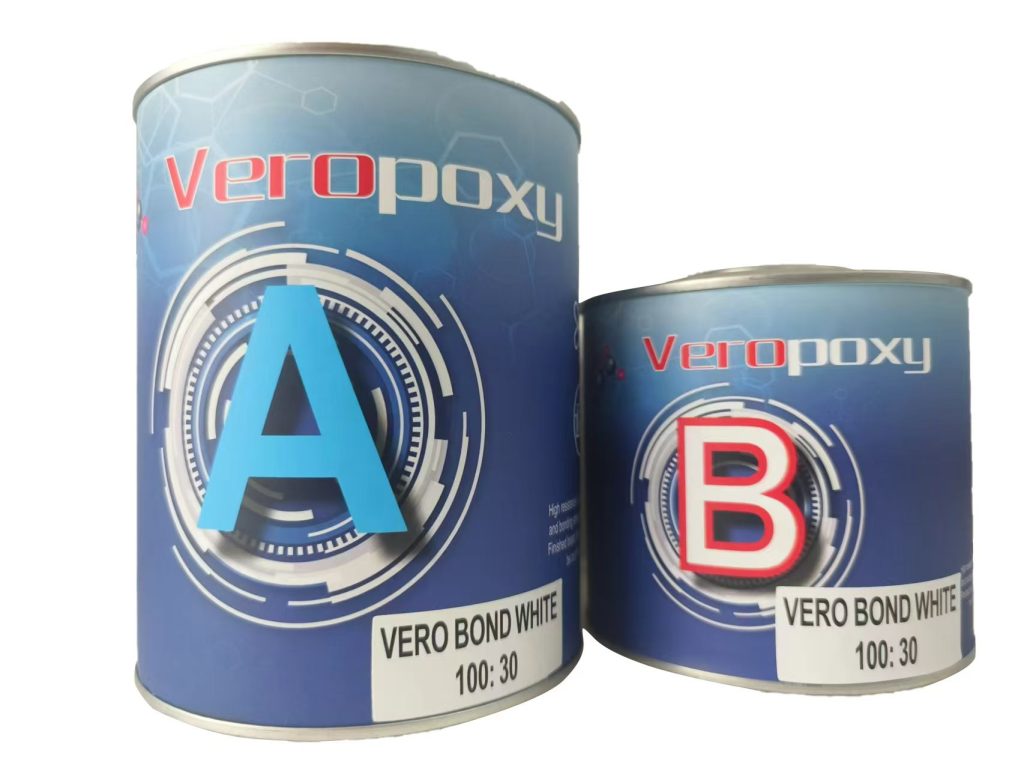

The adhesive strength of epoxy resin on travertine depends largely on the interaction between the resin and the stone’s surface. Mixing epoxy resin—a two-component system consisting of resin and hardener—results in a strong bond by chemical reaction. Offering a better degree of protection than many other sealants, this bond can greatly increase travertine’s resistance to wear, moisture, and temperature changes.

The porous nature of travertine means that epoxy resin must fill these voids and bind to the stone’s surface. This bonding technique guarantees that the resin gets far into the pores of the stone, so producing a more strong and coherent construction. Applied properly, epoxy resin not only offers adhesive strength but also helps to seal the stone, so lowering its staining and water penetration sensitivity.

Factors Influencing the Adhesive Strength

1.Surface Preparation: The surface of the travertine must be properly cleaned and prepared before applying epoxy resin. Any dirt, dust, or oils might compromise the resin’s and stone’s bond. Roughening or sanding the surface will enable the resin to penetrate more precisely, so strengthening the adhesive bond.

2.Environmental Conditions: Temperature and humidity play a significant role in the curing process of epoxy resin. Should the resin be used under extreme conditions, it might not cure correctly, so compromising the bond strength. To get the best adhesive strength, then, moderate conditions of application of epoxy resin are necessary.

3.Epoxy Resin Quality: The type and quality of epoxy resin used also impact its adhesive strength. Specifically meant for stone and masonry uses, higher-grade resins will offer more bonding strength than less-quality resins.

4.Application Technique: Even the best resin can fail to achieve its full bonding potential if it is not applied correctly. Applying epoxy resin in thin, even layers will help to avoid air bubbles and guarantee complete contact with the stone surface, so optimising results.

The Benefits of Using Epoxy Resin for Bonding Travertine

1.Increased Durability: Once cured, epoxy resin creates a highly durable bond that can resist mechanical stress, temperature changes, and moisture exposure. For travertine used in places like countertops, flooring, and exterior cladding, where the stone is subjected to heavy traffic and environmental stresses, this makes it particularly helpful.

2.Enhanced Aesthetic Appeal: Epoxy resin also helps preserve the natural beauty of travertine by sealing its porous surface. This keeps the stone from staining and discolouring from moisture or other pollutants, so preserving its rich, natural look.

3.Cost-Effectiveness: Using epoxy resin for bonding and reinforcing travertine is often more affordable than replacing damaged tiles or stone panels. Epoxy resin can extend the lifetime of travertine surfaces with correct application, so lowering the demand for regular repairs or replacements.

The adhesive strength of epoxy resin in the application of travertine is undeniable. Epoxy resin can improve the structural integrity, visual appeal, and lifetime of travertine surfaces by means of correct preparation and application. Working with travertine, epoxy resin shows to be a useful and dependable solution whether used to bond tiles, fix cracks, or offer a protective seal. Its capacity to preserve and strengthen this delicate stone makes it an essential instrument for both new projects and restoration since it guarantees that travertine will remain shining despite natural deterioration.

Post time: 11 月-07-2024