Marble has long been prized for its luxurious look, from ancient sculptures to modern kitchen countertops. Marble is durable, but it can chip, crack, and age; hence, a repair material that will blend naturally and offer a long hold is needed. Now add epoxy resin for marble, a go-to glue with a strong, invisible bond resistant to elements and time. Not all epoxies are made equally, though, and bonding epoxy resin to marble surfaces has subtleties. Let’s investigate some fascinating features of this special adhesive relationship and discuss why epoxy resin is such a great fix for marble repair.

Epoxy resin

The Science Behind Epoxy Resin for Marble

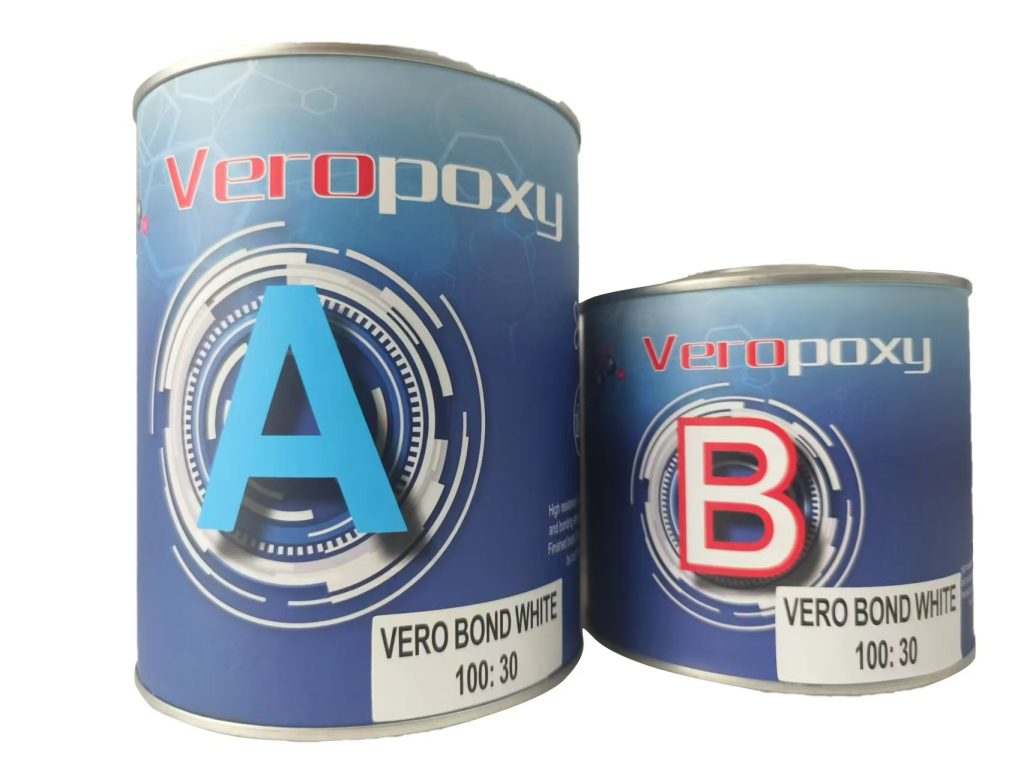

Epoxy resin is known for its two-part system, consisting of a resin and a hardener. A chemical reaction takes place when combined that results in a durable, plastic-like surface hardening of the mixture. Epoxy resin is a pleasing choice for bonding porous materials, including natural stones like marble because of its great bonding strength. Because epoxy resin can seep into the small pores of the stone to form a long-lasting mechanical link, it performs especially well for marble. Marble surfaces especially depend on this great adherence since it lets the resin strengthen the stone without sacrificing its natural feel or appearance.

How Epoxy Resin Enhances Marble’s Aesthetic and Functionality

One of the key appeals of using epoxy resin on marble is its versatility. Epoxy resin is perfect for either filling a minor crack or totally restoring a broken piece. It can be left clear or tinted to match the colour of the marble to produce almost no visible repair. Epoxy resin for marble can also improve the stone’s general durability by shielding it from moisture, heat, and stains—elements that sometimes threaten marble surfaces over time. For seamless repairs, the resin’s sanding, polishing, and shaping qualities make it especially flexible.

Application Challenges and Solutions

Despite its many benefits, applying epoxy resin for marble can be challenging. Marble’s glossy, smooth surface is naturally beautiful; occasionally it resists bonding. The marble needs to be completely cleaned and gently roughened to attain ideal adhesion and let the resin grip better. Additionally, epoxy resin is sensitive to temperature and humidity, so the working environment needs to be carefully controlled. Knowing these subtleties can help one distinguish between a disappointing repair and a strong bond.

Epoxy Resin for Marble and Its Unique Resistance Qualities

One of the standout characteristics of epoxy resin is its resilience. Epoxy resin cures to become heat-resistant, chemical-resistant, waterproof—qualities that make it perfect for marble surfaces often subjected to these elements. As a protective layer, epoxy resin can also shield marble from stains and spills that might discolour the stone. Marble not only gets repaired but also has some long-term preservation added by epoxy resin, so preserving the natural beauty of the stone.

A Look at Different Epoxy Resin Formulas for Marble

Not every marble project calls for every epoxie. While some formulations are made especially to resist extreme temperatures or heavy weights, others are best for clarity and mixing on delicate surfaces. Selecting the appropriate epoxy resin for a marble project depends on knowledge of the particular requirements of the surface you are working with. For outdoor uses, for example, UV-stable epoxies are ideal; for marble countertops in kitchens, food-safe epoxies are best.

How to Apply Epoxy Resin for Marble Repairs

Applying epoxy resin on marble surfaces takes a bit of practice and a few essential steps. For better adhesion, first make sure the marble surface is clean and somewhat rough-turned. Apply the resin and hardener mixture gently to prevent bubbles, which might compromise the bond and appearance, after mixing them in the proper ratio. Pouring the resin in layers lets each cure somewhat before adding the next for deep cracks. Done correctly, epoxy resin for marble can produce repairs as flawless and seamless as the original stone itself.

Epoxy Resin for Marble as a DIY Solution

Although some people would rather call experts for marble repairs, epoxy resin for marble has gained popularity among do-it-yourselfers also. For those seeking a reasonably priced repair solution, epoxy resin applications can be handled with relative simplicity using easily available kits, thorough instructions, and internet tutorials. But the accuracy needed can be difficult, particularly for complex marble patterns or extensive repairs.

The Durability Factor: How Long Does Epoxy Resin on Marble Last?

The fact that epoxy resin for marble lasts is among its most enticing features. Epoxy resin creates a strong, long-lasting bond unlike other adhesives that can resist daily wear and tear. Epoxy is a sustainable option for marble repairs since once cured it can last years without losing its hold. Over time, though, elements including direct sunlight, changing temperatures, and heavy use can affect the resilience of the resin.

Maintaining Epoxy Resin on Marble Surfaces

Epoxy resin is tough, but it still needs some care to keep the marble looking its best. Gentle, non-abrasive cleaners will help to preserve the marble as well as the resin by cleaning the surface A light polishing helps to restore the lustre of the epoxy resin for a marble surface, so enhancing shine. Frequent inspections for minor chips or cracks can also help identify problems early on, so guaranteeing that the repair stays strong and successful.

The union of epoxy resin for marble brings together durability, aesthetics, and functionality in one remarkable solution. It provides strong support against daily challenges and a means of prolonging the life of marble surfaces, so preserving their elegance and beauty. Whether your marble maintenance tool of choice is professional or do-it-yourself, epoxy resin can be quite useful. Epoxy resin transforms repair into a transforming process with appropriate application and care, so guaranteeing the lifetime performance of your marble surfaces.

Post time: 11 月-08-2024