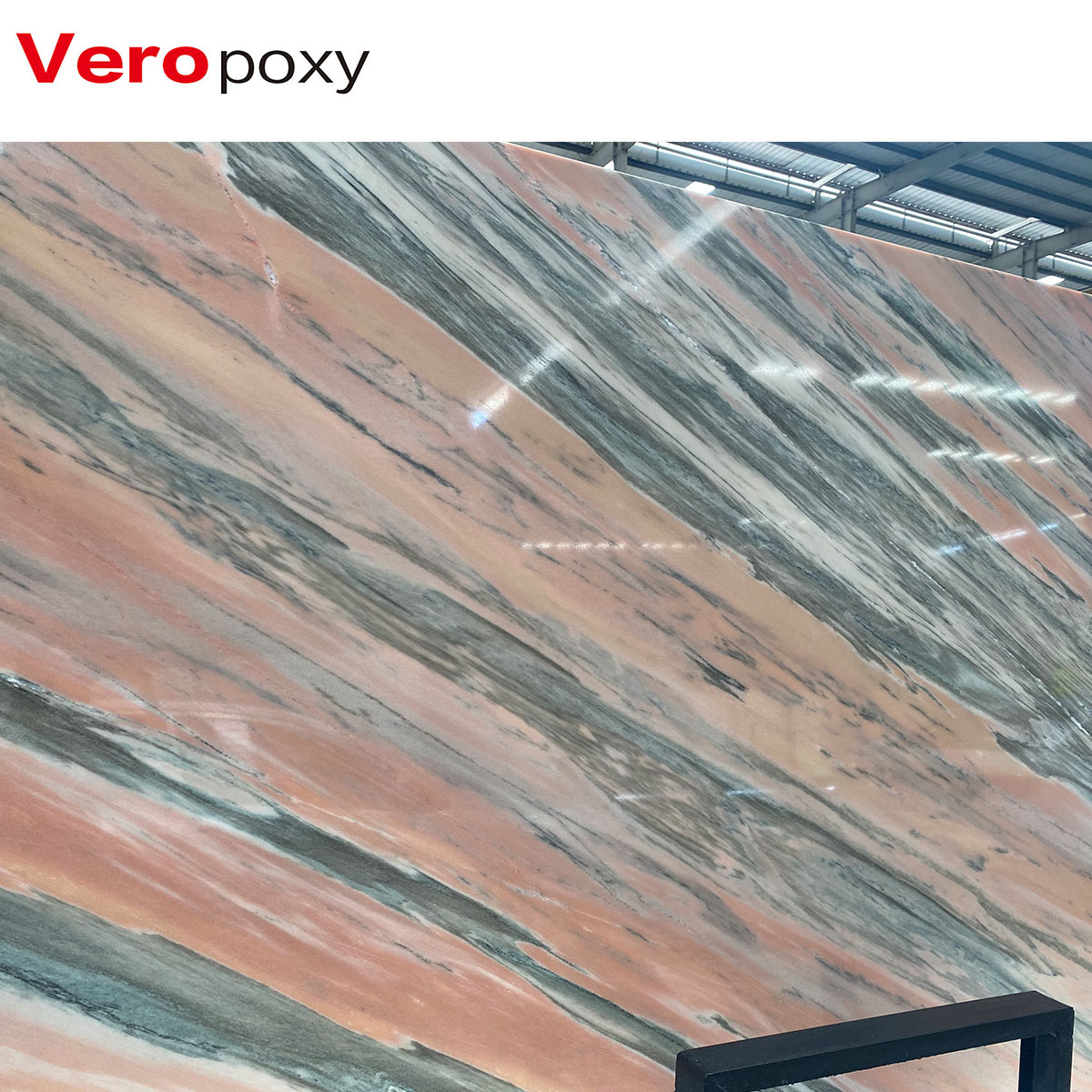

Wholesale epoxy resin kit combination hot sale applied to marble slab

- Feature: Epoxy Resin for soft Marble

- Applicable material: Epoxy Resin for soft Marble

- Epoxy system code: 4090BF+D30M-BSFS

- Epoxy system ratio by weight: 100:30

- Curing effect: Forms a liquid sealing layer

Overview

Veropoxy is a premium supplier of epoxy resins specifically designed for marble slabs, providing superior protection and enhancement. It enhances the wear and chemical resistance of marble, highlights its grain and color, and increases its durability. Ideal for interior design, furniture making and artistic expression.

Product Description

Epoxy Resin Sealant for Marble

The Epoxy Resin for Marble is a high-performance sealing material specifically designed for porous stones like Marble. It effectively penetrates the cracks and pores in the stone, forming a solid sealant layer after curing, which achieves a long-lasting and reliable water-blocking effect. This product features high viscosity, low surface tension, and excellent penetration capabilities, ensuring efficient application on various surfaces of Marble.

Product Features

| Feature | Epoxy Resin for soft Marble |

|---|---|

| Applicable Material | Epoxy Resin for soft Marble |

| Epoxy System Code | 4090BF+D30M-BSFS |

| Epoxy System Ratio by Weight | 100:30 |

| Curing Effect | Forms a liquid sealing layer |

| Durability | High stability and long-lasting after curing, good yellowing resistance, low viscosity, strong bonding, low watermark effect |

| Ease of Use | Easy to mix and apply, no special tools required |

Product attributes

| Attribute | Details |

|---|---|

| Origin | China |

| Main Raw Material | Epoxy Resin |

| Application | Construction |

| Name | Epoxy Adhesive |

| Classification | Two-Component Adhesive |

| Brand | Veropoxy |

| Adhesive Type | Resin Epoxy Resin |

| Application | Rough Surface Coating and Sealing |

Environmentally friendly enhancer for marble slabs

With the improvement of environmental awareness, epoxy resin, as an environmentally friendly material with low volatile organic compounds (VOC), is becoming more and more popular in the market. It is not only environmentally friendly, but also does not produce harmful chemicals during the curing process, ensuring the indoor air quality. This environmentally friendly feature makes epoxy resin an ideal choice for interior decoration, especially in home and commercial environments. It not only improves the performance of marble slabs, but also meets the pursuit of healthy life by modern consumers.

Usage Instructions:

Clean the surface of the Marble to ensure it is dust and oil-free.

Mix the epoxy resin and hardener in the ratio specified in the instructions.

Use a specialized tool to inject the mixed epoxy resin into the cracks and pores of the Marble.

Allow the epoxy resin to cure completely, which usually takes 24 hours.

After curing, if necessary, sand and clean the surface.

Precautions:

Use this product in a well-ventilated area.

Keep out of reach of children and pets.

Read the product manual carefully before use.

Epoxy resin storage

Performance and service lifetime of epoxy resin depend on its storage conditions. First, epoxy resin should be kept away from direct sunshine and high temperatures in a cool, dry surroundings. Usually, the advised storage temperature falls between 15 and 25 degrees Celsius. Second, the container must to be tightly sealed to stop moisture and pollutants from getting in and compromising resin quality.

Furthermore, routinely examine the storage condition to guarantee no deterioration or leaks. Should it not be utilised for a long period, it is advised to first test it on a modest scale to guarantee that its performance still satisfies criteria. Effective extension of the service life of epoxy resin and guarantee of its efficacy in practical uses depend on proper storage.